|

|

|

|

FT

8440415

Maj.1: 05.02.16 |

PDF

|

|

|

|

FT849 Shower by Adler

|

|

FT842 Showcase by Adler (fr)

|

|

FT839 Adslide

|

|

|

FT860 aluminium profiles by Adler VF

|

|

FT857 Shower Clip-in-door

|

|

FT855 Shower Walk-in

|

|

FT853 Shower by Adler VF

|

|

|

Catalogue hinges and hardware

for glass enclosures :

shower, doors...  |

|

|

|

|

CAPSI 90° Wall/gl Hinge – Chrome bronze

on flat wall profile 38x5 |

CAPSI 90° Gl/gl Hinge - Chrome bronze |

|

|

Wall/gl Clamp – Chrome bronze

On flat wall profile 25x5

|

Wall/gl and Gl/gl Stiffener– Polished Stainless steel 20x20 |

|

Details of a construction with profiles on non flat walls

|

|

REVERSI 90° Gl/gl hinge – Brushed stainless steel bronze |

REVERSI Wall/gl Hinge – Brushed stainless steel bronze |

|

Wall/gl and gl/gl stiffener – brushed stainless steel

20x20 |

Details of a construction without profiles

on perfectly flat but non-vertical walls

The lateral glass is trapeze-cut. |

|

|

|

|

|

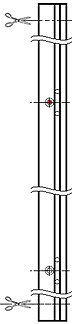

REVERSI self-closing hinge on a thin & flat wall profile (38x5)

The hinges are screwed directly into pre-drilled and taped holes. It simplifies their set-up, especially verticality and C to C between hinges. |

REVERSI hinge on compensation wall profile

(25 to 32 x 25).

The CAPSI or REVERSI hinge then no longer has a wall bracket. With a thickness of 21mm, it blends into the extension of the solid wall profile made of a Tee. The hinge is screwed onto and a U glued and screwed to the wall in which the Tee slides.

|

|

|

Clamp on flat wall profile (25x5)

The clamp is screwed into the profile by 2 M5 screws at its centre. Very easy fitting and high strength. The clamp fastened to the wall holds the fixed glass panel.

|

Clamp on wall compensation profile (25 to 32 x 25)

The 57x57 square clamp has the same size as the hinge: perfect homogeneity, pure design, sleek lines. As with the hinge, on a compensation profile, the clamp is screwed by the back of the Tee profile. The mobile part of the profile and the clamps form a complete set.

|

Design |

Choosing between CAPSI and REVERSI |

|

|

CAPSI is a model registered by ADLER SAS. The screws fastening the hinge onto the glass door are on the outer side and hidden by screw caps with a shape extending the wall fastening claws typical of ADLER self closing hinges. These self-adhesive metal screw caps (brass or stainless steel) bond perfectly with the back plates and will not fall over time. They are manufactured with great care, and can be customized: screen printed with your company name, lacquered, finish caps different from those on the hinge … |

|

|

REVERSI features the same mechanism as CAPSI. All construction elements are identical, down to the back plate, which in REVERSI includes wider blading to house the screw caps. REVERSI’s motor plate and back plate assembly is reversed with respect to CAPSI: to return to a usual fitting with apparent screws on the inner side.

From the outside, REVERSI offers the most minimalistic design possible: a 57x57mm square, “2/3 of a business card”. |

|

Hygiene - Maintenance

CAPSI’s perfectly smooth motor plate avoids nearly all scaling traces from lasting … This simplifies even more cleaning of the shower cubicle door.

Please note that as REVERSI, according to the model chosen or as an option, CAPSI may be fitted with cork, transparent PET or aluminium shims. All these materials offer high resistance of the attacks by water and chemicals in shower, hammam, sauna atmospheres.

Resistance

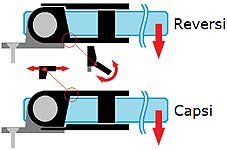

In applications with a high risk of forcing the door beyond 90° outward opening – such as fittings in certain gyms, hotel rooms, where shower cubicle or toilet doors may be found, not bearing against a wall but at the centre of the room; and which may be neglected -, ADLER SAS recommends using CAPSI rather than REVERSI. By reversing the assembly of strictly identical components, in this case of abnormal loading, REVERSI tends to break in flexion for an overload of a few kilogramme forces at the end of the door, while CAPSI offers higher strength by a factor of about 10, as the constraint no longer applies in flexion but in traction. |

|

|

|

| Photo of a REVERSI hinge forced beyond 90° opening. |

|

Assembly diagram of REVERSI and CAPSI hinges and illustration of the effect of an overload at end of door. |

|

Choosing the right CAPSI or REVERSI ? |

Saloon or Isodouche

At ADLER SAS, ISODOUCHE® and SALOON® have been known for nearly 40 years as reference hinges for their finish, quality, and more particularly their self-closing performance. The only difference between these 2 versions is the cam shape.

With CAPSI® and REVERSI®, ADLER SAS has radically simplified and improved the performance of these mechanisms to achieve:

- with extreme miniaturisation, the highest level of transparency of your glass constructions, and,

- with advanced and patented mechanical principles (*), and the use of above standard materials, the highest precision in closing and construction of sealed and gasket free shower cubicles or partitioning of offices without floor pivots …

With CAPSI and REVERSI, the now highly precise self-closing position deserves being finely adjusted to ensure perfect closing of a door extending a fixed partition, or double doors together. The closing angle is adjustable over the entire opening range, from -90° to +90°; the total opening range with respect to perpendicular to the hinge fastening plane remains naturally +/- 90°, regardless of the self-closing position adjustment. |

|

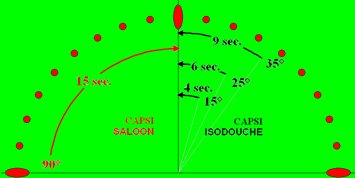

With CAPSI Isodouche, the self-closing range is widened: theoretically from +/-45° around the closing position (offset by ), within the limit of +/-90° total opening. For safety purposes, and to cope with acceptable assembly imperfections (e.g. slight misalignment of the upper and lower hinges) and friction torque resulting from a heavy door, an automatic closing range of +/-30° is used. Thanks to a reduced self-closing angular range, the ISODOUCHE version is that ensuring the most accurate closing, remaining effective with the heaviest doors. |

|

In the case of CAPSI Saloon, the effective self-closing range is +/-90° around the closing position. If the latter is offset with respect to the hinge’s normal to the fastening plane, in one direction the opening, and hence self-closing will be limited to 90° opening; and in the other, beyond 90° opening with respect to the closing position, and still within the limit of 90° opening with respect to the fastening plane, the hinge will no longer close automatically. Because of the widened self-closing range, this SALOON self-closing is weaker than ISODOUCHE, and is actually effective only for lighter and narrower doors, ideally gates below 35 kg with a maximum width of 90 cm. |

|

THEREFORE, where very precise closing of large or heavy doors is required, use the ISODOUCHE model.

(*) For more details on the mechanical principles of the CAPSI, see § How does self-closing of a CAPSI hinge work?"

Door weight

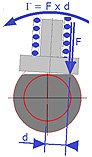

Self-closing precision – in other words, closing of the door by automatic self-closing CAPSI hinges – is particularly related to residual self-closing torque to the closing position. If this torque is high, when a load is applied to the door tending to open it, the self-closing torque opposes the opening, and tends to close the door. This is how closing precision is achieved.

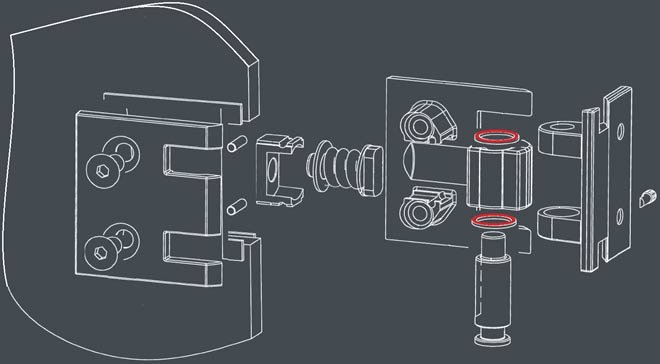

CAPSI and REVERSI hinges are the fruit of several compromises to optimize each of the following criteria: hinge miniaturisation; self-closing torque and closing speed; closing precision. For example, it would be easy to design a hinge of the CAPSI type withstanding 140 kg doors, while maintaining the « motor » assembly: piston, cam, spring… although this would require enlarging the hinge to house the system necessary to reducing the friction component resulting from the door’s weight. The 12mm diameter cam in special steel treated at 1.500 MPa and used as shaft will never break. Even when very thin, the wall bracket is made of an “aluminium brass” alloy about 3 times stronger than cast brass or stainless steel: it also offers very high strength. However, the door’s weight induces a friction torque of the moving hinge part on the wall bracket claws: this torque increases with the door weight. When the door becomes too heavy, the friction torque becomes too high with respect to the weight of self-closing exerted by the piston on the cam: the hinge no longer self-closes. |

|

Assembly diagram of a CAPSI hinge

(In red, the 2 bearing washers of a CAPSI hinge: the lower one supports the door’s weight.

Its friction reduces the effective residual self-closing torque of the hinge).

|

Inside the highly compact CAPSI – or REVERSI - hinge, to increase the acceptable weight of the door without hindering the hinge’s performance, the effect of this weight on friction torque must be reduced. Special washers are then recommended for particular applications with very heavy doors: metallurgic treatment of these bearing washers reduces their friction ratio to about 1/3 what would be possible with Teflon for example …

Only PRESTIGE models use such bearing washers. PRESTIGE hinges are recommended for doors exceeding about 40 kg.

Self-closing quality |

|

To achieve the best self-closing precision, CAPSI pistons are metallic. They offer the rigidity required for perfect guiding of the piston’s pressing face with an accuracy exceeding 0.1° with respect to the door plane. When the piston is metallic, piston and cam must be made of extremely hard metal to withstand the contact loads involved and never chip. Made of steel, the levels of hardness required are about 1,500 MPa.

To ensure the effective self-closing torque is as high as possible, all internal friction components of the hinge must be mastered.

|

The cams, but also the pistons, of the CAPSI benefit from a series of extraordinary surface treatments in the hardware, but which alone reduce the friction ratios by about one third what can be achieved with Teflon for example.

Certain variants of CAPSI and REVERSI however are fitted with a piston in very hard plastic: the particular shape of the piston ensures sufficient stiffness to obtain above-standard characteristics in terms of self-closing– precision and speed. As rather cheap solutions, these hinges are unable to rival the perceived quality and lifetime of 100% metal models – without mentioning applications with high temperatures and degree of humidity… - compared with 100% metal models.

Design

ADLER SAS recommends thorough tightening of the back plate on the plate. Only this can guarantee the door’s stability over time without ever retightening. The thickness of the opening between plate and back plate hence tightened is about 13 mm. Appropriate shimming is recommended for perfect behaviour of the door in this air gap.

CAPSI and REVERSI are proposed with 3 different types of shims according to the model:

- Cork shims: a traditional solution for shimming metal and glass parts, butyl cork certainly remains one of the safest, most effective, cheapest and most user-friendly solutions in the market. For CAPSI, due to the hinge’s level of miniaturisation, ADLER SAS recommends a 50% cork compression rate after tightening on the glass: and not the merely 25% recommended by professional rules. These CAPSI shims, with a thickness of 3, 5 and 6 mm, allow fastening 10, 8 and 6mm thickness glass respectively. NOTE: in the case of 6mm glass, the shim’s compression rate is merely 42%, which remains broadly sufficient considering the maximum weight reached with a 6mm thick door.

- PET shims: PET is a very hard plastic material; transparent in the case of ADLER shims, which shows only glass and metal; user-friendly (100% recyclable) and food-grade. It is hence a good solution chosen by ADLER SAS to ensure effective glass tightening. Tightening at 10N.m is possible per 100mm² shim useful areas: which is 25N.m tightening per screw in the case of a CAPSI hinge. Hence tightened, the door is secured. As PET at these load levels is rather non-compressible, 2.5, 1.5 and 0.5 mm thickness shims are proposed for 8, 10 and 12mm thickness glass respectively. Primary PET sheets have a poorly calibrated thickness. It may be necessary to add a 0.5mm shim to a 2.5mm shim for full tightening, as required, of 8mm thick glass: when possible, before mounting an 8mm glass, check the thickness of the 2.5mm shims. If below 2.3mm, add a 0.5mm shim on the motor plate side; if below 2.1mm, add a 0.5mm shim on either side of the glass.

- Aluminium shims: aluminium offers the benefit of being perfectly calibrated in thickness. It is a metallic, rather inert and 100% recyclable metal. With a same modulus of elasticity as glass, it allows risk-free and very strong tightening of the glass in the hinge. ADLER SAS recommend this solution in many situations: more particularly, refer to the ADLOCK and ADSLIDE ranges, but also ADLER VF. For its range of hinges optimised for shower cubicle walls in 8mm glass, ADLER SAS proposes 100% metal solutions in standard: also ideal for hammams, saunas,…

Particular assemblies

Domed glass

As CAPSI and REVERSI hinges are miniaturised, they are suited to tightening domed glass within the limit of a minimum domed radius in the hinge footprint of 1m25 for 8mm glass. In this case, to compensate the curvature of the glass at the tightening spot, the shims must be made of cork.

Ideally, the glass must not be too thick: 8 mm is a good compromise. Thicker glass leaves a residual shimming thickness which rapidly becomes too weak with respect to the deflection to be absorbed. Too thin a glass may be distorted, and in extreme cases break under the differential tightening pressure.

|

|

|

|

Sauna and hammam, even roaster…

For 8mm glass, a quality/price optimised solution is proposed: metallic piston, standard bearing washers and 2.5mm thick aluminium shims. This solution is designed specifically for the construction of sealed gasket-free shower cubicles, without profiles between the doors…

100% metallic, these hinges are also an ideal solution for the construction of sauna, hammam. In roasters, they dampen the casement and hold it in an open self-closing position. |

|

Mounting on compensation profiles or wall profiles

The safest, fastest and simplest method for mounting a CAPSI door or façade assembly certainly consists in using massive, rigid profiles, and hence frames the façade. Fitting is then quite comparable with that of wooden windows or doors. Adjustable inflatable shims (ADLER ref. = 18650X) or wooden shims (ADLER 378-380 family) allow easy shimming of this frame vertically in its plane. Perfect vertical shimming perpendicular to the door closing plane (or frame plane in general) is still necessary to ensure the hinges can provide perfect self-closing: the verticality defect of a chassis perpendicular to its plane (and the closing plane of the doors) must remain well below 3 mm for a 2m height.

|

|

Wooden doors

Up to 21 mm thickness, a wooden door can be jointed by a pair of CAPSI hinges to benefit from all advantages of automatic high precision closing, double effect (opening in the 2 directions). Generally (beyond 13mm thickness), particular countersinking of the door at the location of the hinges is necessary.

Beyond 21 mm thickness, it remains possible to articulate advantageously a wooden door using CAPSI hinges: the excess thickness beyond 21mm must be contained on the side required of the hinge, which then becomes single effect, i.e. it can be opened only in the other direction. To prevent breakage, it is highly recommended to stop the door in its closed position, near its free end.

|

|

|

|

| Equivalence other finishes: |

|

|

|

|

Operation of the CAPSI hinge self-closing |

|

The hinge’s self-closing « motor » allowing automatic closing of the door comprises a piston pressed strongly against a cam. The cam is fixed with respect to the frame: fixed wall or glass supporting the hinge: its angular position is indexable. The piston is linked to the door and hence turns circumferentially around the cam. The stable self-closing position is when the piston presses flat on the cam’s flat. Once the door half-open, the piston moves up on the edge corresponding to the cam flat: the spring (already pre-loaded) compresses even more and the self-closing lever arm is at its maximum. Hence, according to the spring’s pre-load, the self-closing torque is adjustable to the opening angle of the door, but normally always maximum at the self-closing position: this ensures self-closing precision when all guides and the construction are rigid. |

|

Selon le principe décrit précédemment, il apparaît clairement que seul le principe de rappel fondé sur l’interaction des plats d’une came et d’un piston permet simplement de réaliser un rappel précis et durable ; qui plus est, sur un angle assez grand. Les rappels courants exercés par un doigt d’indexage dans une rainure ne sont précis qu’aussi longtemps que le diamètre du cylindre d’indexage est légèrement plus grand que celui de la rainure avec laquelle il doit coopérer. Les contraintes en jeu tendent à réduire rapidement ce diamètre du cylindre d’indexage, surtout s’il est en matière plastique. |

|

|

|

| ISODOUCHE / SALOON compared closing speeds |

Closing cycles and oscillations of the door with a CAPSI Isodouche and an indexing hinge.

Closing precision / Imprecision |

|

Self-closing torque according to the opening angle of the door of the different models of hinges:

- Black: CAPSI Isodouche

- Red: CAPSI Saloon – in the closed position, the torque is nearly 7 times below that of an Isodouche, hence a precision and closing speed well below.

- Blue: indexing hinge – at the self-closing position, torque is zero. It stays at zero, because of the frictions, over a typical range of +/-3°: i.e. a closing inaccurate at +/-4cm for an 800mm wide door. With CAPSI Isodouche, the precision is +/-0.1°, within the millimetre.

|

Assembly manual |

|

CAPSI REVERSI hinges offer radically new solutions for fastening, self-closing and closing of your doors. To allow the hinge to be miniaturised the force and precision of its self-closing; its improved sealing, the fastening and adjusting principles of your hinge are new and require your attention. |

|

CAPSI |

REVERSI |

|

Fastening on the wall or wall profile:

|

Before assembly onto the door, the hinges must be fastened to the wall profile or the template used to drill the wall with 4 holes perfectly aligned, and with the exact centre distances.

Reminder: The wall must be flat. The hinge axes must be aligned perfectly.

The quality of the medium and screwing in the wall is essential for the installation’s durability.

|

FASTENING ON GLASS: |

The distance between the plate and back plate clamped on the glass must be around 12.5 – 13 mm, whatever the glass thickness. If this distance is too small, the return spring is stuck and the hinge blocked. If too big, opening the door in one direction will be impossible.

Therefore, shimming must compensate the glass thickness differences from one installation to the other. Always observe with precision the shim thicknesses recommended (See table). Centre the hinge properly in the notch.

|

| Glass thickness |

6mm |

8mm |

10mm |

12mm |

| Cork shims |

2 x 6 mm |

2 x 5 mm |

2 x 3 mm |

|

| Aluminium shims |

|

2 x 2,5 mm |

|

|

| Plastic shims |

|

2 x 2,5 mm(*) |

2 x 1,5 mm |

2 x 0,5 mm |

(*)Plastic’s thickness is not precise. If the shims measure less than 2.1mm, add a 0.5mm shim to each side of the glass. If the shims measure less than 2.3mm, add only 1 shim of 0.5mm thickness on the plate side.

The tightening screws must be tightened fully (nominal torque 24 N.m).

NEVER REUSE SHIMS ALREADY COMPRESSED DURING SEVERAL HOURS.

The final total thickness of the hinge fastened to the glass must be about 22 mm.

Before fitting the door between the plate and back plate, place 1mm thickness shims on the wall U-bolts to ensure the shims and the glass notch do not rub on the U-bolt axis.

|

ADJUSTING THE SELF-CLOSING POSITION ADJUSTING THE SELF-CLOSING POSITION: |

The hinges are delivered without self-closing mechanism. Once the assembly mounted, place the door in the self-closing position required and hold it firmly there. In this position, thoroughly screw the screws without locking head of the self-closing cam position; of all hinges equipping the same door. IMPORTANT: WHEN THE CAM OF ONE OF THE HINGES AT LEAST HAS BEEN BLOCKED, NEVER PIVOT THE DOOR WITHOUT THE CAMS OF ALL HINGES BEING BLOCKED THEMSELVES. Non compliance with this instruction may result in the final adjustment being highly complex; or it may lead to heavily degraded operation of the self-closing.

THE SELF-CLOSING POSITION IS FROZEN ONLY ONCE ALL BLOCKING SCREWS HAVE BEEN TIGHTENED THOROUGHLY.

|

FITTING SCREW CAPS: |

The screw caps supplied with the CAPSI range are in pre-glued decorated metal for better behaviour over time. Once glued, they can no longer be destroyed (for example, by drilling at the centre of the cap with a 1 mm dia. drill). ADVICE: GLUE THE SCREW CAPS AT THE VERY END OF YOUR WORK, ONCE THE ENTIRE INSTALLATION ACCEPTED. |

A COMPREHENSIVE RANGE OF SEALED AND GASKET-FREE SHOWER CUBICLES |

Definition of the opening direction: |

|

By principle, we always stand outside the cubicle and open the door either by pulling it, or by pushing it, as our hinges are usually double effect.

When the hinge is on the right, the casement is said to be left (« left pushing » or « left pulling »); when the hinge is on the left, opening is performed with the left hand and the casement is said to be on the right (« right pushing » or « right pulling »).

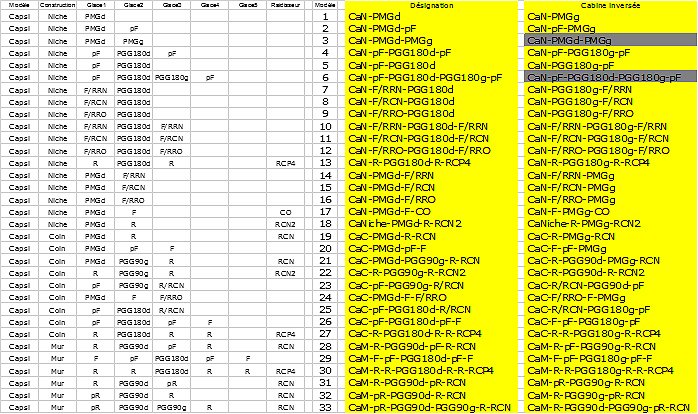

Principle of the designation of shower cubicles:

Description in the order of the glasses, seen from the outside, from left to right.

5 types of main glasses:

- P (door): comprising with the r or l extension (for left or right opening), in:

- PMG: Wall/Gl door;

- PGG90: Gl/Gl door 90°;

- PGG180: Gl/Gl door 180°;

- F (fixed) requiring to be stiffened;

- pF (small Fixed) not requiring a stiffener (typically with width below 300mm);

- R (Return… but which can also be used on façade): it is higher than the door as stiffened by a stiffener running above the door in its full travel;

- pR: an R of small width, not requiring to be stiffened by a stiffener but used to stiffen via a stiffener, another R.

When a stiffener is fastened to a fixed (F or R), it is described in the cubicle’s designation just after the fixed wall it is fastened to. When it is used to stiffen the entire construction by inter-connecting the glass walls, it is described at the end of the entire description. 2 types of stiffeners: RC (square stiffener 20x20), RR (round stiffener dia.25x2). These stiffeners can be fastened in 4 ways: N (normal –or perpendicular-), P (parallel), or N and P simultaneously then described as N, finally O (orientable, typically 45°). In the P and N&P versions (described as N), a number (2 or 4 typically) completes the designation to indicate the number of fastening points perpendicular to the stiffener in addition to the normal fastener(s) at the end. Therefore, we can read RCN, RCP4, RCN2, RRN, RRP4, RRN2, and RRO…

Definition of the 33 reference models:

To define a first version of the configurator. Type of cubicle =

- Ca for Capsi, Re for Reversi – concatenated with N (Niche), C (L in an Angle) or M (U against a Wall);

- Then follows the description of each of the glasswork elements of the construction according to the previous definition.

|

Schematic diagram |

3D CAD model |

Designation |

Short description |

Description |

|

|

Model

N°1 : CaN-

PMGd |

Capsi-Niche

1 Door: /

1 Wall-Gl

pulling opening right |

The « basic » shower wall. A single swing door seals a niche cubicle with the most basic design. Ensure the plan and equipment of your bathroom allows full movement of the door while leaving natural access to the shower cubicle. |

|

|

Model

N°2 : CaN-

PMGd-pF |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

pulling

opening right |

One door and one fixed: the fixed glass allows the door to avoid the footprint of a radiator, a towel holder, a unit or cabinet; or just limit the movement width and volume of the door. |

|

Model

N°2 : CaN-

PMGd-pF |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

pulling

opening right |

The sleekest design of a wall with door and fixed wall. Elegant and effective, this niche façade is limited to a fixed width below 30 cm and ideally a niche width below 1m10. |

|

|

Model

N°14 : CaN-

PMGd

-F/RRN |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

1 Stiffener:

round 20

pulling

opening right |

When the width of the fixed glass exceeds 30 cm, it should be stiffened to prevent accidental breakage or tearing of the wall fasteners. A stiffener, 20x20 mm square or 25 diameters round remains an aesthetic, minimalist and highly transparent solution, the most effective mechanically. |

|

|

Model

N°15 : CaN-

PMGd

-F/RCN |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

1 Stiffener:

square25

pulling

opening right |

|

|

Model

N°16 : CaN-PMGd

-F/RRO |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

1 Stiffener:

Orientable round

pulling

opening right |

A fixed glass wider than 30 cm must be stiffened. To limit its footprint on the shower volume, or drill the cubicle’s back wall, the Stiffener can be fastened slanted between the glass façade and the lateral wall of the niche, ideally close to the glass angle. The turning Stiffener, round (diam.25), forms with the fixed wall and corresponding lateral wall of the maximum angles of 90 deg. |

|

|

Model

N°17 : CaN-PMGd

-F-CO |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

1 Stiffener:

Connector

pulling

opening right |

An original solution, with minimum footprint, to stiffen a fixed glass with a width between 30 and 50 cm consists in forming a cleat with an Adlock angle connector. In this case, the wall on the fixed wall side must be particularly flat: for the construction, no profile, flat or compensation can be used on this side. |

|

|

Model

N°18 : CaN-

PMGd

-R-RCN2 |

Capsi-Niche

1 Door:

/1 Wall-Gl

1 Fixed

1 Stiffener:

Tube 1 Point

pulling

opening right |

Out of all solutions to stiffen the fixed glass of a width exceeding 30 cm, the latter, highly original and typically Adler, is the only requiring no wall drilling to fasten the stiffener when the construction is made with wall profiles: flats or compensation. |

|

|

Model

N°3 : CaN-

PMG-PMG |

Capsi-Niche

2 Door:

/1 Wall-Gl |

Two doors, or one door and a gate. An original alternative, particularly elegant and minimalist, to all configurations with a door and a fixed wall. For absolute transparency, forget even the door button! |

|

|

Model

N°5 : CaN-pF-

PGG180d |

Capsi-Niche

1 Door:

/1Gl-Gl

180 deg

1 Fixed

pulling

opening right |

One fixed, and a door articulated on the fixed. The fixed glass allows to move the door’s rotation axis away from the wall; hence the full opening of the door flat on the radiator, the towel holder, the wash basin unit… the depth of which defines the width of the fixed glass. |

|

|

Model

N°5 : CaN-pF-

PGG180d |

Capsi-Niche

1 Door:

/1 Gl-Gl

180 deg

1 Fixed

pulling

opening right |

The most simple and transparent solution as long as the width of the fixed glass remains below 30 cm and 80 cm for the door. |

|

|

Model

N°7 : CaN-

F/RRN-

PGG180d |

Capsi-Niche

1 Door:

/ 1Gl-Gl

180 deg

1 Fixed

1 Stiffener:

Round 25

pulling

opening right |

Beyond 30 cm wide, the fixed glass is no longer rigid enough to withstand the door. The latter may touch the floor during its movement on either side of the return position and oscillating torque exerted by the door on the fixed glass at each beating may tear its anchors. To be stiffened with a stiffener, square (20x20 mm) or round (diam.25). |

|

|

Model

N°8 : CaN-

F/RCN-

PGG180d |

Capsi-Niche

1 Door

: /1 Gl-Gl

180 deg

1 Fixed

1 Stiffener:

Square 20

pulling

opening right |

|

|

Model

N°9 : CaN-F

/RRO-PGG180d |

Capsi-Niche

1 Door:

/1 Gl-Gl

180 deg

1 Fixed

1 Stiffener:

Round orientable

pulling

opening right |

To limit the footprint of the stiffener in the volume of the shower cubicle or avoid drilling the back of the cubicle, a round stiffener (diam.25) orientable (0-45 degrees) allows squaring the fixed glass onto the corresponding lateral wall of the niche: the latter must form an angle below or equal to 90 degrees with the fixed glass. |

|

|

Model N°6 : CaN-pF-PGG180d-PGG180g-pF |

Capsi-Niche

2 Door:

/2 Gl-Gl

180 deg

2 Fixed |

A double façade with four panels, with doors articulated on fixed for very large niches or, otherwise, bathroom configurations where the movement surface of the doors must be limited: the doors can even become gates, of a width of about 30 cm each. Here, the width of the fixed glass must remain below 30 cm. |

|

|

Model N°4 : CaN-PGG180-

2F-d |

Capsi-Niche

1 Door:

/1Gl-Gl

180 deg

2 Fixed

pulling

opening right |

A façade with a door framed by two fixed glasses. This construction allows moving the door articulation away from the corresponding wall to escape any footprint of a towel dryer, a unit or a window… The second fixed can be a simple solution to ensure minimum play at the end of the door without considering imperfections of the second wall; or the effective way to limit the door’s width. |

|

|

Model

N°4 : CaN-

PGG180-

2F-d |

Capsi-Niche

1 Door:

/1 Gl-Gl

180 deg

2 Fixed

pulling

opening right |

A simple and light solution to be recommended as long as the width of the fixed glasses does not exceed 30 cm, and 80 cm for the door. |

|

|

Model

N°10 : CaN-

F/RRN-

PGG180d

-F/RRN |

Capsi-Niche

1 Door:

/1Gl-Gl

180 de

2 Fixed

2 Stiffener

Round 25/

Round 25

pulling

opening right |

Beyond 30 cm width, the fixed glass is no longer rigid enough to support the flag fastened door. It may touch the floor when moving on either side of the self-closing position, and the oscillating torque exerted by the door on the fixed glass at each beating may tear the anchors. To be stiffened by a stiffener, square (20x20 mm) or round (diam.25). It is strongly recommended to also stiffen the second fixed glass if its width exceeds 30 cm. |

|

|

Model

N°11 :

CaN-F

/RCN-

PGG180d

-F/RCN |

Capsi-Niche

1 Door:

/1Gl-Gl

180 deg

2 Fixed

2 Stiffener:

Square 20/

Square 20

pulling

opening right |

|

|

Model

N°12 :

CaN-F/

RRO-PGG

180d

-F/RRO |

Capsi-Niche

1 Door:

/1Gl-Gl

180 deg

2 Fixed

2 Stiffener:

Round Orientable/

Round Orientable

pulling

opening right |

To limit the footprint of the stiffeners in the volume of the shower cubicle or prevent drilling the back of the cubicle, round orientable stiffeners (0-45 degrees) (diam.25) allow squaring the fixed glass to the corresponding lateral walls of the niche: these must form an angle below or equal to 90 degrees with the façade. |

|

|

Model

N°13 : CaN-R-

PGG180d

-R-RCP4 |

Capsi-Niche

1 Door:

/1Gl-Gl 180 de

2 Fixed

1 Stiffener:

Tube 2 Point

pulling

opening right |

Out of all the solutions available to stiffen fixed glass with a width exceeding 30 cm, this highly original and typically Adler approach is the only one which requires no wall drilling to fasten the stiffener: it is merely screwed very strongly in applique by 2 Adlock points on each fixed glass. A very simple assembly guaranteeing effectiveness. |

|

|

Model

N°19 :

CaC-

PMGd-R

-RCN |

Capsi-Angle

1 Door:

/1 Wall-Gl

1 Fixed:

1 Lateral

1 Stiffener:

Square 20

pulling

opening right |

The simplest model for an angle shower wall. The stiffener is required when the lateral glass exceeds 30 cm. When the angle partially forms a niche and the lateral glass is sufficiently narrow, using a stiffener is no longer useful: the door and return glass are then aligned in the upper section. |

|

|

Model

N°20

: CaC-

PMGd-pF-

F

|

Capsi-Angle

1 Door:

/ 1 Wall-Gl

2 Fixed:

1 Lateral/

1 Façade

pulling

opening right |

An angle cubicle with a door fastened to the wall and two fixed glasses forming the angle: a solution particularly interesting when the cubicle’s width remains below 1m30 and the fixed glass on façade is sufficiently narrow (30 cm maximum) to stiffen the return glass without using a stiffener. |

|

|

Model

N°20

: CaC-

PMGd-pF-

F |

Capsi-Angle -

1Porte:

/1Mur-Glace

- 2Fixe:

1Lat�ral/

1Fa�ade - ouverture

tirant droite |

An elegant solution to limit the size and displacement surface of the door, and avoid the presence of a stiffener and height offsets between the façade and the return. To be used only when the width of the fixed façade glass is less than 30 cm. |

|

|

Model

N�24 : CaC-

PMGd-F-

F/RRO |

Capsi-Angle

1 Door:

/1 Wall-Gl

2 Fixed:

1 Lateral /

1 Façade

1 Stiffener:

Round Orientable

pulling

opening right |

When the fixed glass on the façade must be wider than 30 cm, it should be stiffened in the upper part. An orientable stiffener limits overlapping on the cubicle’s volume and avoids having to drill the back wall. The stiffener’s fastening point is located near the angle of the fixed façade glass to maximize the stiffener effect and be aligned with the ground clamp. |

|

|

Model

N�23 :

CaC-

pF-PGG90g-

R/RCN |

Capsi-Angle

1 Door:

/ 1Gl-Gl

90 deg

2 Fixed:

1 Lateral/

1Façade

1 Stiffener:

Square 20

pulling

opening gauche |

Angled for optimized shower access despite the dimensions of the contiguous wall, the door may be fastened to the return glass. In this case, the return must be stiffened. |

|

|

Model

N°23 :

CaC-

pF-PGG90g-

R/RCN |

Capsi-Angle

1 Door:

/ 1Gl-Gl

90 deg

2 Fixed:

1 Lateral/

1Façade

1 Stiffener:

Square 20

pulling

opening gauche |

De façon traditionnelle, mais avec un raidisseur Adler particulièrement résistant : rond en diamètre 25 ou carré de 20, la glace de retour est sécurisée et rigidifiée. Le fixe en façade est ici supposé mesurer moins de 30 cm de largeur. |

|

|

Model

N�22 :

CaC-R-

PGG90g-R

-RCN2 |

Capsi-Angle

1 Door:

/1 Gl-Gl

90 deg

2 Fixed:

1 Lateral/

1 Façade

1 Stiffener :

Tube 1Point

pulling

opening gauche |

Out of all the solutions available to stiffen the return glass, this highly original and typically Adler approach is the only one which requires no wall drilling to fasten the stiffener: it is merely screwed very strongly in applique by 2 Adlock points on each fixed glass. A very simple assembly guaranteeing effectiveness. |

|

|

Model

N�21 :

CaC-PMGd

-PGG90g-R

-RCN |

Capsi-Angle

2 Door:

/1 Wall-Gl

/ 1 Gl-Gl

90 deg

1 Fixed:

1 Lateral

1 Stiffener:

Square 20 |

This shower wall is ideal for many comfortable but narrow bathroom configurations, where the contiguous wall is fitted with a towel dryer … The double door fully benefits from the self-closing precision of Capsi hinges. It offers unequalled free access to the shower. Transparency is also enhanced when using button-free doors. |

|

|

Model

N�25 :

CaC-pF-

PGG180d-R

/RCN |

Capsi-Angle

1 Door:

/ 1Gl-Gl

180 deg

2 Fixed:

1 Lateral/

1 Façade

1 Stiffener:

Square 20

pulling

opening right |

When a towel dryer or a unit restricts opening of the door fastened to the wall, the alternative to a shower wall with double door is one fixed and one door articulated on the fixed. The fixed glass allows locating the door’s rotation axis away from the wall. |

|

|

Model

N�26

: CaC-pF-

PGG180d

-pF-F |

Capsi-Angle

1 Door:

/ 1Gl-Gl

180 deg

3 Fixed:

1 Lateral /

2 Façade

pulling

opening right |

The fixed glass on the wall side on façade can be used to compensate a verticality or slight flatness defect without wall profile by means of a transparent seal or in the colour of the wall facing (white, grey or black, etc.) It also allows adapting to a towel dryer by offsetting the door’s rotation axis. The second fixed limits the door’s width and its footprint on the bathroom; while ensuring effective stiffening of the return wall. |

|

|

Model

N°26

: CaC-pF-

PGG180d

-pF-F |

Capsi-Angle

1 Door:

/1 Gl-Gl

180 deg

3 Fixed:

1 Lateral/

2 Façade

pulling

opening right |

An original and highly transparent construction for rather large and stiffener-free angle shower cubicles. The fixed glasses may measure up to 30cm wide. With a door of 70 to 90cm on average, the cubicle can already measure 1m30 to 1m50! The fixed panels can be fastened to floor profiles. |

|

|

Model

N�27 :

CaC-R-

PGG180d-R-

R-RCP4 |

Capsi-Angle

1 Door:

/ 1 Gl-Gl

180 deg

3 Fixed:

1 Lateral /

2 Façade

1 Stiffener: Tube 2 Point

pulling

opening right |

When at least one of the fixed glasses must be widened beyond 30cm, it must be stiffened. The stiffener links the 2 fixed glasses together, without being fastened either to the wall or the return wall: it remains very simple and pure, without spacer to move it away from the façade. The passes under the stiffener to open in both directions. On the floor, small prongs can be used to fasten the glasses. |

|

|

Model

N�28 :

CaM-R-

PGG90d-

pF-R-RCN |

Capsi-Wall

1 Door:

/ 1 Gl-Gl

90 deg

3 Fixed:

2 Lateral /

1 Façade

1 Stiffener:

Square 20 - pulling

opening right |

The simplest model of shower wall fastened against the wall: on the façade, the fixed glass with a width of less than 30cm and fastened onto the threshold strip stiffens the return glass; the latter, via the Stiffener, stabilizes the second lateral wall the door is flag-fastened onto. This model is ideal for cubicles up to about 1m20 long. |

|

|

Model

N�29 :

CaM-F-pF-

PGG180d

-pF-F |

Capsi-Wall

1 Door :

/ 1Gl-Gl

180 deg

4 Fixed:

2 Lateral /

2 Façade

pulling

opening right |

Both lateral walls are stiffened by the fixed glasses squared on the façade. This construction allows the door’s rotation axis to be offset and avoiding a towel dryer, unit, etc. La The width of the fixed glasses on façade is adapted to limit the width of the door and its footprint on the bathroom. |

|

|

Model

N°29 :

CaM-F-pF-

PGG180d

-pF-F |

Capsi-Wall

1 Door :

/ 1Gl-Gl

180 deg

4 Fixed:

2 Lateral/

2 Façade

pulling opening right |

An original and highly transparent construction for rather large shower cubicles without stiffener fitted against a wall. The top of the façade is continuous. The fixed glasses can measure up to 30cm wide. An average door between 70 and 90cm allows the cubicle to already measure 1m30 to 1m50! The fixed panels are to be anchored to the floor with profiles. |

|

|

Model

N�30 :

CaM-R-R

-PGG 180d

-R-

R-RCP4 |

Capsi-Wall

1 Door:

/ 1 Gl-Gl

180 deg

4 Fixed: 2 Lateral /

2 Façade

1 Stiffener:

Tube 2 Point

pulling

opening right |

When at least one of the fixed glasses must be widened beyond 30cm, it must be stiffened. The stiffener links the 2 fixed glasses together, without being fastened to the return walls. Therefore, its design remains very pure, without spacer to move it away from the façade. The door, which must maintain its opening in both directions passes under the stiffener. On the floor, small prongs can be used to hold the glasses. . |

|

|

Model

N�31 :

CaM-R-

PGG90d

-pR-RCN |

Capsi-Wall

1 Door:

/ 1Gl-Gl

90 deg

2 Fixed:

2 Lateral

1 Stiffener:

Square 20

pulling

opening right |

In the case of particular constructions, half-« angle », half- « against a wall », the narrow lateral wall – with a width less than about 30cm – is sufficient to stiffen the entire construction via a stiffener. The façade can then be made of a single door for a minimalistic design. |

|

|

Model

N�32

: CaM-pR-

PGG90d

-R-RCN |

Capsi-Wall

1 Door:

/ 1 Gl-Gl

90 deg

2 Fixed:

2 Lateral

1 Stiffener:

Square 20

pulling

opening right |

In the case of particular constructions, half-« angle », half- « against a wall », the narrow lateral wall – with a width less than about 30cm – is sufficient to stiffen the entire construction via a stiffener. The façade can then be made of a single door for a minimalistic design. |

|

|

Model

N�33

: CaM-pR-

PGG90d-

PGG90g-

R-RCN |

Capsi-Wall

2 Door:

/2 Gl-Gl

90 deg

2 Fixed:

2 Lateral

1 Stiffener:

Square 20 |

In the case of particular constructions, half-« angle », half- « against a wall », the narrow lateral wall – with a width less than about 30cm – is sufficient to stiffen the entire construction via a stiffener. The façade can then be made of a double door for a minimalistic design, with optimum access to the cubicle… fully benefitting from the performance of Capsi hinges. |

Reversing a construction: |

If the last term in the designation is a stiffener for the entire construction, it remains the last term in the designation of the reverse construction. All other terms in the description will be grouped in the reverse direction. The door opening direction will also be reversed: the l extension becoming the r extension, and vice versa. |

Choosing wall profiles: |

|

|

|

|

To fasten wall clamps or hinges onto compensation profiles, a width of 25mm is sufficient. The edge of a standard 8mm glass is centred on the profile which protrudes by about 8mm. The fastening holes are covered by the glass edge: a single reference of profiles in stock includes the 2 fastening centre distances: 1m55 and 1m80. These profiles are also used to fasten CLIP-IN DOOR and ADLER VF hinges.Chrome brass: 78014R (flat) and 78011N (compensation); brushed stainless steel: 78015S and 78012P respectively. |

|

|

|

An even more discrete construction can be achieved using flats rather than compensation profiles. To fasten hinges while leaving them removable, they must be screwed on the façade. The flat fastening profile of CAPSI hinges is then 38mm wide. The countersunk screwing holes in the wall are then fully covered by the hinge wall plates. 2 centre distances between the fastening holes are available in standard in stock: 1m55 and 1m80. 2 standard finishes: chrome brass (( 78004F for 1m55 and 78002C for 1m80) and brushed stainless steel (( 78005G for 1m55 and 78003D for 1m80). |

For very simple stiffener fastening, without drilling the wall, offset fastening plates are fastened directly onto the 25mm wide profiles. |

|

|

|

The width of the flat wall profile for fastening Capsi hinges is sufficient to fasten the stiffener directly in an additional tapped hole prepared by ADLER as per your dimensions. |

The entire construction also includes floor profiles (threshold strips), in both finishes, with or without fastening points (tapped holes) for clamps under fixed glasses. |

|

|

Wall profiles or not? |

Choice: TECHNIQUE |

CAPSI and REVERSI hinges are very precise; however, to ensure all the self-closing torque is released, when fastened the hinges must be perfectly aligned with each other and without stress.

A « biased » hinge fitting naturally blocks the movement of any hinge, usually forcing the door to close in an intermediate position offering the minimum average distortion of the door under the contradictory effect of both hinges.

For example for a shower wall or corridor separation door, which closes with a one-millimetre accuracy at the door’s end, the hinges must be perfectly free and aligned.

|

| The only correct assembly: fixed hinges, with axes perfectly aligned together. |

|

Many incorrect assemblies to be avoided absolutely and leading to improper operation of the hinges: automatic closing inoperative, early hinge damage, up to breakage; and excessive solicitation of the anchoring points, up to tearing from the wall. |

|

|

|

|

|

|

Therefore, direct fastening of the hinges onto a wall which is not perfectly flat is just forbidden! Correcting the flatness defects of a wall merely by shimming the back of the hinge wall plates is not possible, and requires delicate masonry work.

In the case of a non flat wall, ADLER SAS strongly recommends the use of wall profiles, flats or compensation profiles.

Choice: DESIGN

Assembly without wall profile is often demanded. If such a profile-free assembly is not recommended technically, does it really offer an aesthetic benefit? The following photos present the visual impact on a same construction with wall profiles and without these profiles: this is shown with 3 very different wall facings. Here, the profiles are intentionally the largest to highlight the visual impact: 25 x 25mm compensation profiles. A construction with 5mm thick flats is even more discrete.

In all cases, even a 25x25 mm compensation profile is not that visible.

Discrete, located at the end of the glasses, it outlines the glass construction and can become a design element, such as stainless steel frameworks of the doors …

For most non flat walls, the only alternate construction acceptable consists in integrating on – or in – the wall, before tiling, a « U » profile for rabbet assembly which is then virtually invisible. One should though be vigilant, according to the cubicle model chosen: in certain cases where heavy loads may apply to the end of the glass fastened, gluing the glass in the upper and lower pars in the rabbet may prove necessary, as holding by the rabbet seal may be insufficient (**).

(**) The ADSLIDE rabbet system – available in brushed stainless steel– including a 30x12x30x1 « U » profile with an opening of 10 for a glass size 8 with full height transparent rabbet seal on one side of the glass withstands about 50 kg tearing over a full height of 2m.

|

Case N°21 : CaC-PMGd-PGG90g-R-RCN |

with compensation wall profiles |

without wall profiles |

On polished concrete:

The polished concrete surface is mat. The rather thick and chromed finish compensation profile is visible. A profile in « brushed stainless steel » finish would certainly be more discrete on this wall. However, on the lacquered glass lateral wall, hence glossy, the chrome brass wall profile is very discrete. Please note the benefit of such a construction with profile glued on full surface for anchoring a door on such a wall facing.

|

|

|

On driftwood:

The previous comments remain applicable. According to the constructions, the profile |

|

|

On black faience:

According to the constructions and viewing angle, a wall profile glued onto a mosaic surface, particularly when the latter is glossy, is virtually invisible. If additionally the mosaic has an imperfect flatness surface, a wall profile construction is obvious in this case.

can blend with the joints between the wall lathes.

|

|

|

| Choice: INSTALLATION QUALITY & GUARANTEE |

Wall profiles proposed by ADLER SAS were designed to facilitate and secure installation. Applying the method proposed by ADLER SAS to measure the dimensions of your installation and mount the profiles ensures:

- An accuracy of one millimetre in adjustments guaranteeing sealing and looks;

- Durability of wall fasteners over time;

- Drilling which is secured, precise and limited to 2 (limited risk of damage to the wall facing).

Full height gluing of the profiles with appropriate sealant (call ADLER SAS), and pressing against the wall with a rigid mason’s rule ensure simple correction of flatness and verticality defects to guarantee sealing. The metallic parts are screwed directly into pre-machined profiles: accurate, fast, strong assembly guaranteed.

|

Achieving a millimetre precision construction from non flat and non vertical walls |

| Measuring dimensions: correction of verticality and flatness defects in walls |

Most of the time, walls are neither flat nor vertical. This means down to one millimetre precision as the final construction requires this level of precision:

- Which is the clearance between façade glasses;

- To guarantee perfect sealing in normal use; and

- To ensure very pure aesthetics of the shower wall, as with a corridor separation …

Different cases of non flat and non vertical walls are shown below. The dimension measurement technique is always the same, with the sole purpose of determining the thickness of the 2 shims to be fastened at the back of the wall profile to correct all wall defects.

|

Case of a non flat wall: irregular tiling… |

Case of a protrusion in the middle of the wall: for example, thicker frieze. |

Case of a non vertical wall, frequent in renovation… |

Case of a tiling defect with an alignment defect on the upper and lower parts of the wall. |

|

|

|

|

| Installing the profiles |

| Glue 0, 1 or 2 shims at the back of each wall profile according to the defects to be corrected: maximum one on the level of each of the 2 countersunk holes pre-machined in the profile and through which the wall will be counterbored to receive impact screws adapted to the wall, dowell diameter 6mm, to fasten and secure the profile, particularly as long as the sealant has not cured. The following table shows the shimming of the upper and lower profiles, while indicating every time the respective thickness of the 2 shims for each of the measurement cases illustrated previously. |

|

|

|

|

|

|

|

|

| Legend of the previous diagrams |

|

|

|

|

|

A mason’s rule (light, very rigid and perfectly straight), ideally cut at the planned height of the façade (*), is applied against the wall, at the planned façade anchoring point. Ideally it is held vertically using a spirit level. The wall profile countersunk holes are marked with a pencil (centred at 15mm precision, standard centre distance 1m55 or 1m80). A laser allows materializing on the rule a perfect vertical, in a plane perpendicular to the façade to produce: 3 distances from this line vertical to the wall are then measured.

The contact of the rule with the wall shows the wall’s flatness defects and finds the wall’s most protruding point, the one around which the rule turns when nearly vertical.

(*) If the rule is too short, a protrusion at the top of the wall at the façade fastening point may remain undetected. Conversely, a protrusion above the cubicle height may prevent proper pressing of a rule which is too long.

|

|

Measurement of the distances between the vertical (laser beam on the mason’s rule or the tape measure used) and the wall. |

|

|

|

|

|

|

|

Contact point between the mason’s rule and the wall when the rule is vertical. |

|

|

|

|

|

Materialisation of the 1 St measurement point: distance between vertical and the wall at the application point of the mason’s rule. |

|

|

|

The 3 distances measured: A between vertical and the rule’s contact point; B and C, respectively between vertical and the lower and upper screwing points of the profile in the wall.

|

|

|

|

Shimming at the back of the profile |

|

|

|

Thickness of the upper and lower shims |

|

|

|

|

1910 |

Creation of the company |

|

1929 |

A. ADLER |

|

1976

1978 |

Patent of the Isodouche hinge

Development of the Saloon model |

|

1983 |

Patent of the selective blocking hinge |

|

1997 |

Patent of the Venus hinge with ring-type recall system |

|

2006 |

Patent of the precision automatic-return Capsi hinge |

|

|

Z.A. La Barogne - 9, Av des 22 Arpents - 77230 Moussy le Neuf - France

Tel.: +33 (0)1.60.03.62.00 - Fax : +33 (0)1.60.03.62.49

E-mail : commercial@adler-sa.com - Site : www.adler-sa.fr

SAS au capital de 2 014 000 euros . RCS Meaux B562054957 |

|